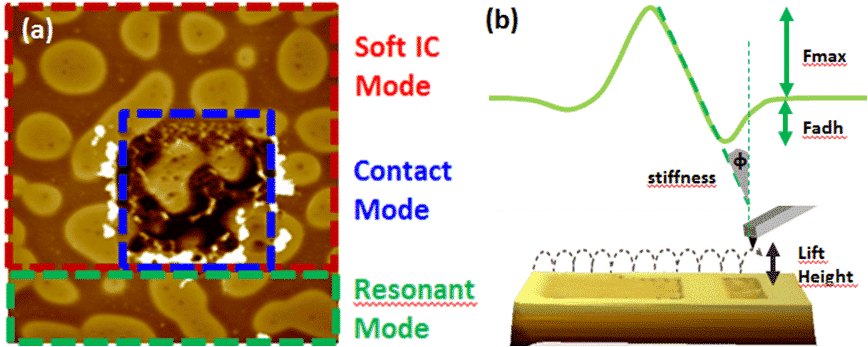

Soft Intermittent Contact : 3rd AFM mode (Soft IC)

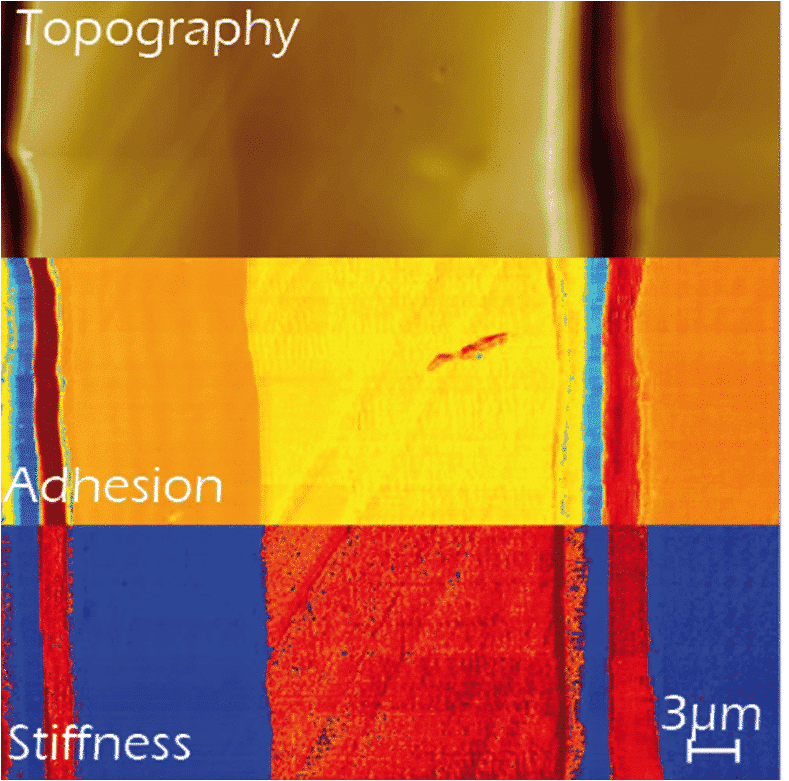

The advantages of contact and resonant AFM modes without the drawbacks

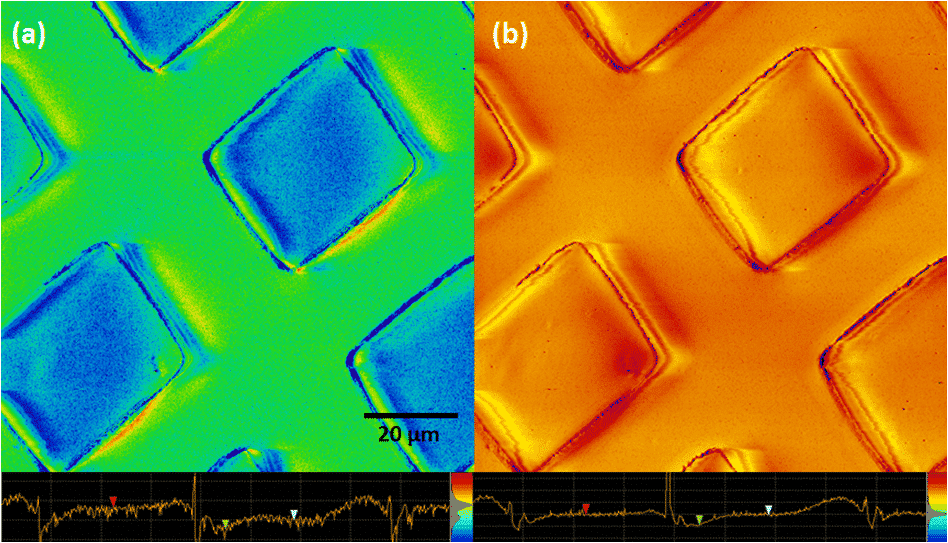

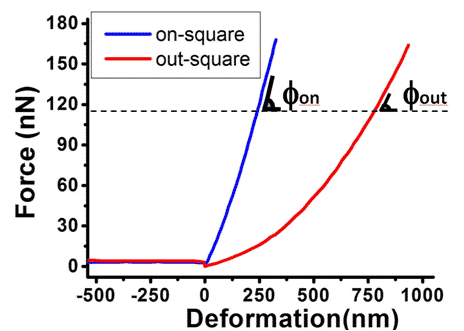

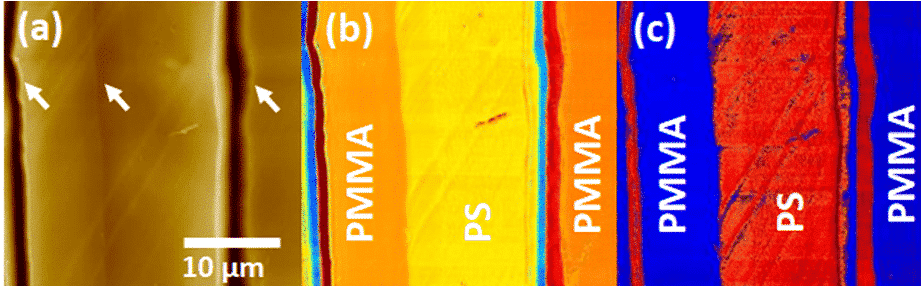

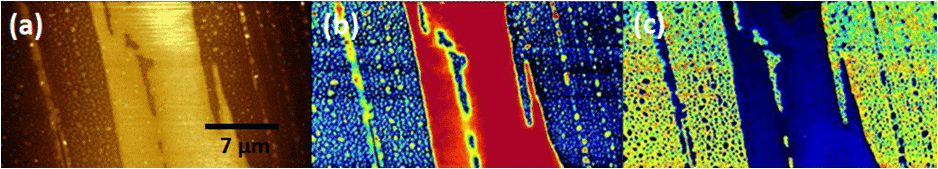

Mechanical properties : Adhesion, Stiffness, Young’s Modulus

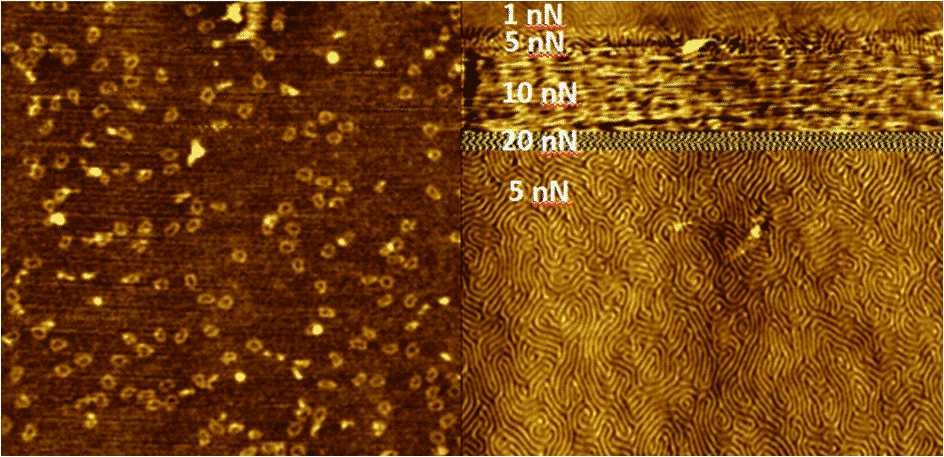

Constant force = quantitative measurement

Compatible with : ResiScope, SThM, PFM, C-AFM…